Sandwich panels are essential materials used across modern industries. They combine insulation, structural strength, and fast installation in one simple yet powerful system. Thanks to their versatility, these panels appear in a wide range of sectors, from cold storage to cleanroom manufacturing.

What Makes Up a Sandwich Panel?

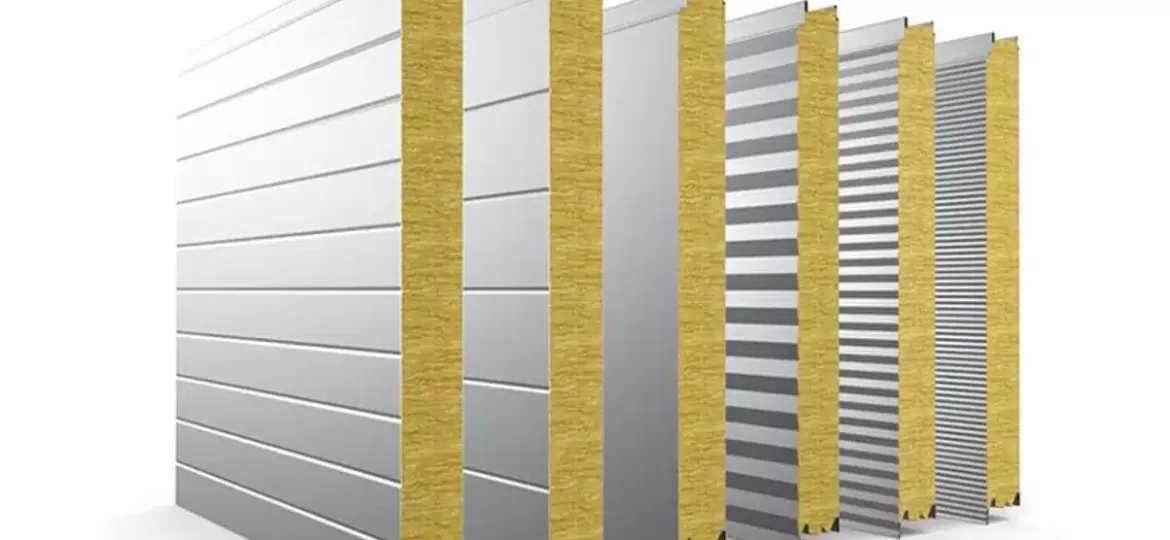

Each panel consists of three layers. Two outer metal sheets protect the core and provide mechanical strength. Between them lies the insulating core, which defines the panel’s thermal, acoustic, and fire resistance properties.

Because each layer serves a unique function, manufacturers can adjust the materials to match specific building needs. As a result, sandwich panels meet both architectural and technical expectations.

Panel Core Materials Compared

To choose the right panel, it’s critical to understand the advantages of each core type. The table below outlines the key differences.

| Core Material | Thermal Conductivity (W/m·K) | Fire Resistance | Main Benefits | Typical Uses |

|---|---|---|---|---|

| PUR | 0.022–0.028 | Low | Excellent thermal insulation, lightweight | Cold rooms, commercial chillers |

| PIR | 0.021–0.026 | Moderate | Fire-resistant, stable under heat | Warehouses, cleanrooms |

| EPS | 0.035–0.038 | Low | Affordable, easy to handle | Temporary offices, partition walls |

| Rockwool | 0.035–0.045 | High | Non-combustible, sound-absorbing | Power plants, schools, fire-rated structures |

Where Are Sandwich Panels Used?

Because they perform well in many conditions, sandwich panels support both functional and aesthetic goals. Let’s explore where they’re used most effectively.

Cold Storage Facilities

In cold rooms and freezer depots, temperature control is everything. Panels with PUR or PIR cores lock in cool air, lowering energy consumption. Furthermore, their seamless joints prevent thermal bridging. This keeps stored goods within safe ranges while reducing operational costs.

Industrial Buildings

Time is money, especially in industrial construction. Therefore, many developers choose sandwich panels for fast and efficient assembly. Panels with PIR or Rockwool cores help meet fire safety codes while still providing strong insulation. Additionally, they reduce the need for heavy framing systems.

Cleanrooms and Laboratories

Clean environments demand strict control over dust, air quality, and bacteria. To address this, PIR-core panels with special coatings are used. Their flat surfaces allow for easy cleaning and minimal particle build-up. Thus, they are ideal for pharmaceutical plants and electronic assembly rooms.

Architectural Façades and Roofs

Modern buildings often require both design and performance. Sandwich panels offer a sleek look without sacrificing protection. Particularly in high-rise or urban buildings, Rockwool-core panels deliver top fire safety while enhancing thermal comfort.

Modular and Temporary Structures

Emergency camps, worksite offices, and mobile housing solutions often depend on EPS panels. They are light, easy to transport, and quick to install. In situations where speed and flexibility matter most, these panels provide a practical solution.

Why Sandwich Panels Make Sense

- Quick Installation: Because panels are pre-fabricated, they reduce on-site labor.

- Energy Efficiency: Their insulation lowers heating and cooling demands.

- Fire Safety: PIR and Rockwool models meet high fire-resistance standards.

- Durability: Panels resist corrosion, mold, and impact damage.

- Acoustic Performance: Especially with Rockwool, they reduce noise transmission.

Moreover, sandwich panels support green building standards by lowering a structure’s energy footprint. They also offer recyclability in certain configurations, which helps meet sustainability goals.

Fire Ratings and Building Code Compliance

Fire resistance is a legal and safety requirement, especially for public buildings. In this context, sandwich panels must comply with strict standards such as EN 13501-1. While PUR and EPS are limited in fire safety, PIR and Rockwool offer much better performance.

- PIR Panels: Reach B-s1,d0 classification

- Rockwool Panels: Achieve A1, the highest level of fire resistance

Builders should always verify fire ratings based on national regulations and project needs.

Final Thoughts

Sandwich panels offer more than just structural cladding. They represent a smart, multi-purpose material that serves diverse industries. By selecting the appropriate core material and panel thickness, project managers can achieve both safety and efficiency.

As construction standards grow stricter and timelines become tighter, sandwich panels continue to prove their value—again and again.

Technical Integrity

At ATABAŞ GRUP, we supply only certified sandwich panels tested for thermal performance, density, fire behavior, and acoustic absorption. Our team works directly with SGS-accredited labs and top manufacturers to ensure all panels meet or exceed global standards. Whether for cold storage or cleanroom assembly, we offer full documentation and tailored engineering support with every shipment.